| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Yuji

Model Number : Coal Fired Hot Water

Certification : ISO CE

Place of Origin : China (Mainland)

MOQ : 1 set

Price : Negotiable

Supply Ability : 5 Sets per month

Delivery Time : 15 days

Packaging Details : wood packet

Product Name : SZL Series 17.5MW 130℃ quality controls Coal Fired Hot Water Boiler

Application : Greenhouse/poultry farm, hot water supply, hospital, hotel

Boiler Usage : Industrial, Power Station, poultry, Storage tank, central heating for residential

Color : Customer's Requirement

Material : Q345R Steel Plate

Pressure : 1.25MPa

Thermal efficiency : 90%

After-sales service provided : Engineers available to service machinery overseas

Product Discription

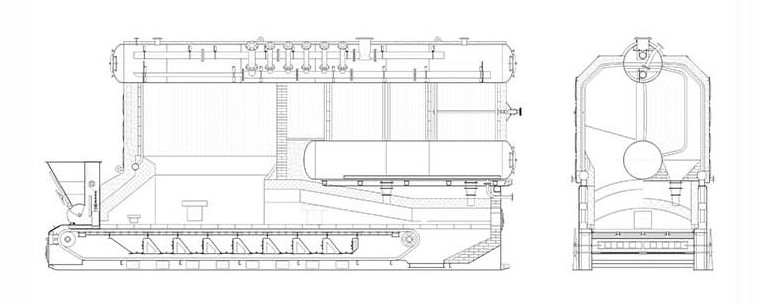

SZL Series Double Drum Chain Grate Biomass Water Boiler

SZL series double drum circuit, two boilers, boiler chain, the main engine design of the boiler vertical two drums V. Install steam separator on top of pipe, install device during downpipe, left and right side of furnace, water-cooled pipe The combustible grate for automatic refueling and refueling is regenerated, convection tube, and the tail part of the grate is Hugo province. Fuel oil from electric heater, fan, mechanical ventilator and automatic slag remover with automatic slag remover enters the furnace with chain furnace. In the combustion chamber, smoke passes through the tail of the combustion chamber, receiver, convection, fuel saver or air heater, in the dust collector, blower, blower. The smoke pipe eventually enters the atmosphere.

Product Features

1. High -efficiency grid:

The boiler employs a two -sided ventilation and dust removal technology which naturally ventilates the front end of the grid, avoids air leakage, oil leakage and uneven ventilation, and i s easy to handle.

2. Removal of light ash:

The boiler can create several ash wells i n order to remove the ash i n a timely and effective manner, avoiding accumulation of ash and reducing thermal efficiency and ensuring the stability of the boiler load.

3. High security:

Water supply is controlled and provided automatically by a computer. Water scarcity, excessive protection and other means, safe and reliable.

4. Life and durability:

Technical design of boilers, advanced production equipment and strict quality control guarantee the quality of each new boiler. The boiler's life span exceeds twenty years.

5. Environment and low noise:

The initial flue -gas discharge of the boiler is low and the tail of the boiler is equipped with an efficient dust collector and a low -noise fan to ensure that the flue -gas discharge complies with national environmental requirements.

6. Production specifications:

Parts of boilers are manufactured in accordance with national and international standards (ISO).In order to ensure reliable product quality, all steps of production are carried out strictly in accordance with advanced manufacturing technology.

Technical Parameters

| Item | Unit | SZL1.4 | SZL2.8 | SZL4.2 | SZL5.6 | SZL7 | SZL10.5 | SZL14 | SZL17.5 |

| Thermal Power | MW | 1.4 | 2.8 | 4.2 | 5.6 | 7 | 10.5 | 14 | 17.5 |

| Outlet Pressure | MPa | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0/1.25/1.6 | 1.0/1.25/1.6 | 1.0/1.25/1.6 |

| Outlet Temperature | ℃ | 95 | 95 | 95/115 | 95/115 | 95/115 | 95/115 | 95/115 | 95/130 |

| Feed Water Temperature | ℃ | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 |

| Thermal Efficiency | / | ≥83% | |||||||

| Fuel | / | Biomass particles | |||||||

| Fuel Consumption | Kg/h | 348.6 | 685 | 938.8 | 1366.2 | 1694.6 | 2583 | 3410 | 4272 |

| Heating area | m2 | 81.26 | 165.26 | 233 | 351.2 | 391 | 547.6 | 826 | 1110 |

| Grate area | m2 | 2.8 | 6.04 | 8.64 | 11.71 | 13.64 | 15.33 | 19.16 | 26.3 |

| Power consumption | Kw | 25.3 | 34 | 62.4 | 76.2 | 87.2 | 138 | 206.5 | 218 |

| water volume | m3 | 3.59 | 6.67 | 8.33 | 8.42 | 12.7 | 13.9 | 15.6 | 18 |

Note: the fuel consumption in the table is calculated on the basis of the low calorific value of biomass particles 17084KJ/Kg (4085Kcal/Kg). If the low calorific value of biomass fuel is larger than this value, the corresponding fuel consumption will be more economical than the value in the table.

External and Interface Dimension of SZL Biomass Hot water boiler

| Item | Unit | SZL1.4 | SZL2.8 | SZL4.2 | SZL5.6 | SZL7 | SZL10.5 | SZL14 | SZL17.5 | |

| Steam Capacity | t/h | 1.4 | 2.8 | 4.2 | 5.6 | 7 | 10.5 | 14 | 17.5 | |

| Transport Dimension

| L | mm | 5600 | 7380 | 6900 | 7000 | 2800 | 8700 | 11900 | 10700 |

| W | mm | 2500 | 2700 | 2660 | 3400 | 3020 | 3340 | 3200 | 3000 | |

| H | mm | 3500 | 3740 | 3500 | 3700 | 3500 | 3570 | 2360 | 4000 | |

| Maximum Transport Weight | / | t | 24.5 | 31 | 30 | 32.5 | 34 | 35 | 35 | 36 |

| Outlet Water Valve | DN | mm | 100 | 125 | 150 | 200 | 200 | 250 | 2*200 | 2*200 |

| Feed Water Valve | DN | mm | 100 | 125 | 150 | 200 | 200 | 250 | 2*200 | 2*200 |

| Safety Valve Diameter | DN | mm | 1*50 | 2*40 | 2*50 | 2*50 | 2*50/80 | 100*80 | 2*100 | 2*100 |

| Drain Valve Pipe Diameter | DN | mm | 2*40/50 | 3*40 | 40/3*50 | 4*40 | 6*40 | 6*40 | 8*40 | 8*40 |

| Chimney Diameter | φ | mm | 350 | 410 | 530 | 720 | 750 | 950 | 1000 | 1200 |

Remarks: We will reserve rights to change the above mentioned data due to continuous policy transformation and product improvement.

|

|

Power Station Coal Fired Hot Water Boiler 17.5MW 130℃ Double Drum Circuit Images |